|

BOATBUILDING WITH A DIFFERENCE

IV

(For Aspiring Amateurs)

by Barend Migchelsen Migchelsen@aol.com

https://ca.geocities.com/bmboats2002/

https://members.aol.com/_ht_a/migchelsen/myhomepage/

| Barend

Migchelsen,

(pronounced Mikkelsen) learned to sail in The Netherlands in 1943. In 1975 he started to

build boats and boat models as a hobby. Today, he organizes and teaches classroom

courses in boat building, and has published several books on the subject. The

following is an excerpt from one of these books. this is the second of three parts.

|

|

In the preceding articles I – III, the mathematical foundation of hard-chined, small-boat design was shown. Once you digest the simple mathematics, lofting becomes child's play. Little was said about the building process itself.

THE CONVENTIONAL METHOD:

Upside Down

For a “newbie” amateur one of the easiest ways to construct a hull is the upside-down method: The cross frames, bow stem, and transom are placed upside down on a building jig. The planks are hung around the frames. The bottom closes up the hull box.

This method is exactly the same as for building the model except that the jig is a ladder frame instead of a single 2"x3" “spine” as is shown in the first photograph of article I.

THE BODY VIEW DRAWING IS THE MAIN GUIDE FOR THIS METHOD!

After the hull is finished most amateur builders have no further use for the building (ladder) jig. If it is screwed together, it is easily taken apart. Completely eliminating the jig is even more efficient.

THE THREE ALTERNATE METHODS

The strongbox method

In the Body view of figure 4-1, a (red) horizontal line is drawn between the Beam stations representing a deck. |

Fig. 4 – 1

The deck line is drawn in red

|

If the full-sized drawing is made on one-inch-grid graph paper, the half-Breadth width of the deck at each station can be read off directly. They are shown in the drawing.

Plot the measurements on a plywood panel. Rip a 1"x2" at flare angle, glue these inwale slats along the plotted points. Cut off the outside excess at flare angle. See the photograph. A Japanese pull saw is ideal for this exercise.

Placed on three sawhorses, the deck panel provides a perfect platform for the rest of the hull construction without the need of a building jig. Attach the carlings. Cut out the cockpit space as shown in the picture. The cross strips are easily removed after the hull is finished.

Place the bulkheads fore of station line #4 and aft of station line #11 on the platform. They are held plumb by a longitudinal bow frame fore of station line #4 and a longitudinal transom frame aft of station #11. Next is the (bottom) half frame at Beam.

My experience is that making notches in the inwales without cutting into the deck and gluing the cross frames in these notches works a lot easier and actually makes the setup stronger than notching the frames over the inwales.

The 1"x1" linings on each side of the longitudinal frames take care of the king planks and the keelson. The cross frames are lined all around in the same way with 1˛x1˛ slats. The model frame in the photographs is mounted on a 1"x2". |

| Sometimes, I hang the side panels first before the chines are placed. The easiest way to attach the chines is on the outside, but IMO that makes an ugly sight. |

Fig. 4 – 2 Three chine solutions

This can be (partly) overcome by the compromise shown in the middle drawing: a 1"x2" is ripped at flare angle and attached as shown. Personally, I prefer the chines on the inside.

After the hull is turned over, if you leave the sides as they are, you end up with a very stiff, comfortable skiff. If you cut the side panels flush with the deck you obtain a flat, Laser-type wet-sailer that will stand up to rough treatment, and that is easy to car-top even if it is made from low-cost, lightweight, 1/8" Lauan. |

| Make sure to seal the insides of the bow and transom (air) chambers before placing the bottom. Plastic resin glue works well for this purpose.

IN THIS BUILDING METHOD THE HALF-BREADTH DRAWING OF THE DECK

IS THE PRINCIPAL GUIDELINE!

You can’t go wrong with this method. All the correct bevel angles of the cross frames are directly taken from the deck contour line.

The strongback-sandwich method

Howard I. Chapelle briefly mentions this method in his Old Testament of the boat-builders' Bible "BOATBUILDING" (1941) on page 199, and illustration #52.

A frame is made in the exact shape of the Profile view projection drawing.

THE PROFILE DRAWING IS THE MAIN GUIDE

FOR THE CONSTRUCTION OF THE PROJECT!

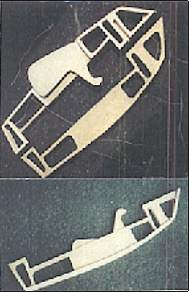

The photograph

at left shows such a frame for the San-Francisco Pelican. Two panels of 1/8" Lauan separated by 1"x2" stock and lined on the outsides by 1"x1" works fast and easy. Remove the excess plywood after the frame is put together. It makes a lightweight, strong "spine" that stands on its own even before the cross frames are attached. The photograph

at left shows such a frame for the San-Francisco Pelican. Two panels of 1/8" Lauan separated by 1"x2" stock and lined on the outsides by 1"x1" works fast and easy. Remove the excess plywood after the frame is put together. It makes a lightweight, strong "spine" that stands on its own even before the cross frames are attached.

It is not necessary to build all the full-sized hulls to obtain the insight and the experience. A to (1/6) scale model made from 2-mm cardboard will do. Actually, making a model of this low-cost material is slightly more difficult than the real "McCoy" because of the smaller tolerances and the cheap quality of the material.

|

The "third" alternate

method

I call it by that name because I can't think of a better name.

If you have tried all the methods mentioned before, you are no longer a beginning amateur but you have become familiar with the measurements. You have gained a lot of insight in the lines and the proportions of a hull.

In this method, you assemble a centerboard box and attach the bulkhead at station #4 and the cross frame at station #8. This is the building jig.

Cut the side panels. Attach the panels to the bow stem. Place the panels on the setup. Line up station line #4 and #8 (Beam) of the panels on the bulkhead (#4) and the (half) cross frame (#8). Hold the side in position with clamps. Bring the panels aft together with a Spanish windlass to attach the transom.

It is the simplest method as long as you know what you are doing, |

The beauty of trying all these methods is that you can do it on the kitchen table during the (too) long North American winter season. It shows you exactly how to prepare the parts of your hull in kit form. It will give you a head start on the (too short) summertime.

Sheers and Chines, Barend. |

|

![]()