|

A Birdsmouth Mast for Skat

by Dave Burdecki (Bink)

binksboats@yahoo.com

| Greetings:

Well...I heard there was some sort of end-of-season football

game yesterday...but I had real work to do. John O'Neil and I (ok,

mostly John} made a beautiful octagonal 14 foot bird's mouth mast for the

Skat. John wrote a couple of articles about the technique in

Boatbuilding and since he lives nearby I begged and whined until he agreed

to show me how its done. |

John O'Neil & the Spruce board

|

|

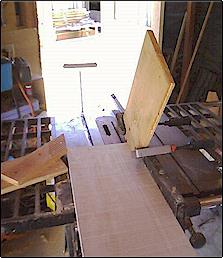

Cutting the strips

|

I bought a 16 foot 1"X12" spruce board. I needed

a mast 3 inches at the base, so the circumference was ...well, this

calculator doesn't have pi on it, so take my word that the circumference

divided by 8 plus the width of the kerfs came out to an 11 1/2 inch wide

board with about an inch leftover. |

| We cut the staves on the table saw then ran them

through again to take off the rough side that would be on the inside of

the mast. This was not strictly necessary, but since that side was

going to be epoxied we went with caution. We set the blade at 45

degrees and cut a 90 degree bird's mouth along one side of the staves by

running each one through the saw twice, once forward, then flipped and run

through again. |

Strips cut

|

|

Cutting the taper

|

Just to be extra fancy, we cut the taper on the table

saw. The stick is straight for 9 feet then tapers for 5 feet to the

top. The taper is from 3 inches to 1 1/2 inches. We cut a 1

1/2 inch wedge from a 5 foot board and used the board as a guide on the

saw. Starting the cut at the 9 foot mark it worked like a champ! |

| Now came the part that everyone dreads...epoxying the

slippery staves and assembling them into a rounded mast. What a

letdown! It was too fast and easy. I slathered while John

mixed. After 3 sides of each stave were coated we used a bottle that

was 1 1/2 inches in diameter (the inside of the mast at the bottom) and

rolled the ends of the staves around it. We fastened them together

with a large hose clamp and then used waxed twine to clamp up the rest of

the mast. |

|

|

A perfectly straight mast

|

He rolled the mast while I walked the spool up the

mast. The whole thing fell into shape as if by magic! Another

clamp at the top and it was all over. We had a perfectly octagonal

and straight mast. After it sets I'll start planing the ridges off

and sanding it round. I took some pics which you can see here.

The whole thing took about 5 hours with lots of breaks. Most of the

time is in setting the table saw and running test cuts.

Bink |

|