New shape for old boat

design modification by Roger Schroeder

(see story

of original design)

After living with my canal boat

as a barge for three years I began to desire something with better

lines, also the fact that we always felt we were plowing through

the water made me long for a shape that could displace water with

a little more grace. The idea to start new was always tempered

with my hesitation to not create scrap out of my barge boat. It

occurred to me that with some modifications I could make my barge

look and perform better.

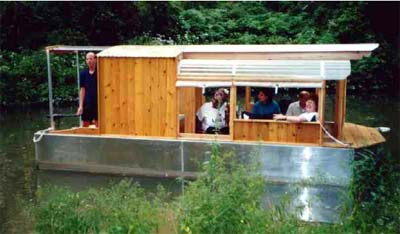

Original look of the canal boat

The design question I pondered

all winter was how to add a more shapely bow. At first I considered

removing the existing bow and replacing it with a new better shape

but that required lengthening the boat and abandoning my current

front. I could of course take the existing bow and use it as a

stern by welding it to the existing transom but that would require

extensive work on both ends. At this point it occurred to me that

I had been looking at this problem backwards ! Why not look at

the current bow as a shapely stern and rebuild the boat backwards.

Wireframe and rendered sketches of my ideas

for changes.

Working in Aluminium

One of the advantages of working in aluminum as a construction

material is that changes are relatively easy. While aluminum is

not a choice for most amateur builders it seems to me it should

be an option. While a 1/8” thick sheet of aluminum is approximately

three times the cost of marine grade plywood it can quickly become

a cheaper alternative when paints, and epoxy coatings are considered.

The aluminum oxide that forms on the surface of exposed aluminum

provides a tough barrier to further oxidation so paints as protective

barrier are not required. Plate thickness of 1/8” is easily

cut with a circular saw and carbide blade (noise and hot chips)

or a

reciprocating saw.

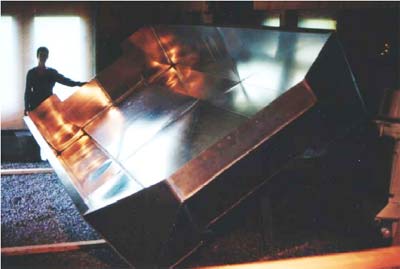

Original hull in process of being rotated

Welding is as a challenge

Welding is the skill that stops most from tackling this method,

but if your can take the time to develop the skill, it can be

an enjoyable process. Imagine making a strong solid finished connection

between two surfaces as fast as you can move the tip of the welder.

I taught myself to weld with enough proficiency to complete a

boat that spent three seasons in the water without leaking (not

a brag if you saw my work up close). The equipment can be had

for less than six hundred dollars spent between Home Depot and

you local welding supply store. Now don’t get me wrong,

welding is more difficult than hot gluing and is at times very

frustrating with wire jams in the machine taking up at least half

of your time, In the end running a good looking solid bead can

feel as good as a long straight drive down the fairway and just

as elusive.

Armed with my recriprocating saw and welder I went to work on

a new look

Back to my project

This hull not being not painted and with removable wood internal

braces changes seem quite doable.

With spring and the purchase of

a reciprocating saw I set to work with some ideas on paper and

more in my head. Cutting the sides free I was curious to see how

easily and cleanly they would curve. I had experimented with 1/8”

x 1 1/2” flat stock but had no idea how a 2’ wide

sheet would bend and as it turns out is bends nicely.

My plan was to free the first

40” of the sides to see how close they could be brought

together and then complete the bow with new aluminum. As it turns

out I could get enough bow of the bow to not need any additional

material and the unsightly welds that would come with it.

This being a flat bottomed boat

the bottom emerged from the sides as they were drawn in and provided

a way to tack weld the sides into position. Once tacked into place

a continuous fillet weld was made on the outside of the hull and

the bottom is trimmed to meet the new bow shape. Water is added

to the hull (overnight rainfall) to expose leaks they are marked

and re-welded. With the hull watertight on the first weld the

interior fillet weld is made.

Allowing the aluminium to take a natural bend the sides were matched,

clamped and tack welded into place.

Reuse and recycle aluminium

Deck surfaces are made using cutoffs from the bottom, in places,

butt welding pieces together to form larger sections. The aluminum

topsides forms watertight surfaces, strengthens hull and reduces

surfaces the require maintenance.

With the exterior trimmed away the internal fillet weld is started.

Deck and Pilot house

The deck /pilot house is constructed from the cedar removed from

the boat and all exterior wood surfaces are stained with Cuprinol

in the same manner you would a house. Brightwork is kept to a

minimum since I leave this boat outside all winter in Buffalo,

New York.

The bifold doors are reused from

the old design and provide a way to get the doors out of the way

when open.

The unsightly welded line where

the deck meets the sides of the hull is masked with wood. This

was my first experiment in laminating wood into a curve. Using

scrap luan underlayment three layer were built

up and clamped using those one dollar spring clamps avalible at

Home Depot. The laminate was then varnished and attached with

stainless steel screws on aluminium brackets to allow removal

during the winter.

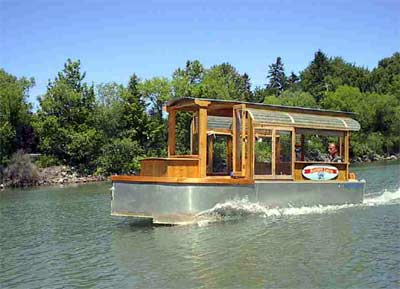

New Pilot house and trim

A New Roof

The corrugated galvanized metal is cheap, a 14’ long sheet

would also cover the new pilot house.

Transom Reconstruction

To allow for a motor to be attached to the old bow (now a stern)

a cutout had to be made. The cut was made deep enough to allow

a 15” motor to be used and made adjustable if a 20”

motor is found. The adjustment is made by creating an aluminium

slot on both sides for a 2” thick plywood transom to slide.

The plywood is now bolted in place for a 15” (short shaft

motor).

New transom cutout

Testing on a Trolling Motor

Concerned that she might not float right I tested her before I

made the commitment to buy a new motor.

Testing her on a trolling motor

she floated fine and moved better than her original incarnation.

Testing with guests at our Memorial Day

Party

The Big Purchase

With a lot of thought I made the decision to power her with a

9.9 Hp 4 stroke. My decision was based on environmental reasons

as well as a consideration for noise.

I purchased a Tohatsu from a local

dealer and she performed better than expected. She trolls quiet

but can move out quite well when needed.

In a twenty mile round trip to

an Erie Canal Fest in Toanwanda, New York we burned less than

three gallons of gas.

Testing with guests at our Memorial Day Party

Full speed with the new 9.9 HP 4 Stroke

Future Work

Plenty of work awaits, but we can still have fun with her. Windows

need to be designed and made, installation of remote steering

at the pilothouse, the construction of an enclosed head and electrical

wiring.

Like its first life as a

barge boat it may never be completed but change and evolve as

I do.

The deck house provides a great perch for sightseeing and sun.

|