|

In Part

I of this series of articles on the design and construction

of the sharpie skiff, Nemah, I outlined the preliminary

development of this design.

Working from a notion of what constitutes a "boat,"

lines were developed for a hull that will be well suited

for its intended uses. In Part II of this series, we will

develop a sailing rig for Nemah, and then consider how

to select and apply various structural techniques to create

a boat that is both strong andlightweight

The Loose-Footed Sprit Rig

The Loose-Footed Sprit Rig

There are several sailing

rigs that produce minimal heeling effect. These would include

the gaff rig, the sprit rig, various types of lug and lateen

rigs, and even some low aspect ratio fully battened jib-headed

rigs. In selecting a rig for Nemah, I was influenced by

several considerations, including length and number of spars,

complexity of the rig to set up and handle, relative performance,

appearance, safety, and cost.

Sprit rigs offer several

advantages for boats of the type and size of Nemah:

- The four-sided shape of the

sail itself eliminates the narrow triangular areas that

do little work, as in many three-sided sails

- The sails are generally lashed to the

mast, eliminating the expense of running rigging and sail

track.

- The rig offers the most driving power

in relation to spar length of any known rig

- The short, stiff irast does not need

to be stayed and is easy to step and unstep without assistance

On the minus side, the sprit

must be properly set to be efficient, and the rig cannot

be reefed in the conventional manner, (Sprit rigs are usually

reefed by folding the peak of the sail down and lashing

it off to the mast, and then resetting the sprit to a grommet

set in the leech for the purpo e.)

The point on the hull where

the sheet is made fast while sailing close hauled, needs

to be far enough off the centerline of the hull, so that

the sail can be sheeted down hard and still be able to draw;

hence the wide transom. In addition, the clew of a loose-footed

sail needs to be enough forward of the stem of the boat

that the sheet can be secured at a point

where it places equal tension on both the leech and the

foot of the sail. This usually requires that the mast be

stepped well forward in the boat, which in turn gives two

advantages:

- It moves the center of effort of the

sail well forward, which is needed to counteract the apparent

weather helm that loose-footed sails demonstrate

- it frees up a generous area forward

of the rowing thwart.

Traditionally, the masts

of loose-footed rigs were sharply raked aft. This has the

effect of keeping the pull of the sheet at an optimum angle

through a greater range of points of sail, as well as shifting

the weight of the mast aft.

In drawing Nemah's rig,

I selected a preliminary length of 12 feet overall for both

mast and sprit, and a target sail area of 80 square feet.

Mast rake was determined by eye and the mast drawn in. I

next drew in the foot, with consideration given to head

clearance and so forth. At this point, I pencilled in a

peak angle and found a likely peak height by moving the

sprit around on the drawing until it formed an even-sided

triangle with the top of the luff. I then sketched in the

leech and checked to see if the clew angle and location

would allow the sail to be properly sheeted in, close-hauled.

(The sheet angle in profile should roughly split the clew

angle.)

At this point I checked

the sail area to see if it was coming out near my target

area. (To determine the area of a four-sided sail, first

divide the sail into two triangles, figure the areas of

each, and then add the two together.) If the sail area had

fallen much outside of my target area, I would have had

to adjust the length of one or both of my spars. Small adjustments

can be made by moving the peak around and then relocating

the clew to maintain the sheet angle.

Daggerboard Location

The location of the sail's

center of effort in relation to the hull's center of lateral

resistance determines the "helm" of a boat; that

is, whether you will need to "pull or "push"

on the tiller to maintain your point of sail. Generally,

you want a bit of "weather helm" both for safety

and because a "lee helm" causes the rudder to

work against thecenterboard, reducing your ability to point.

The center of lateral resistance

is the point at which the total of the sideways resistance

of the hull, centerboard, rudder and skeg is in balance.

This point is generally adjusted to fall 10% to 20% of the

hull length aft of the center of effort of the sail, depending

on the rig. In practice, this relationship varies with weight

distribution, the point of sail, the depth of extension

of the centerboard, and so forth. The trim can be "fine-tuned"

by adjusting the rake of the mast, which moves the center

of effort fore and aft.

Because Nemah

is designed to be operated under power, she must meet

U. S. Coast Guard level flotation requirements. Her

wood hull provides a portion of the requirement, but

some additional buoyancy is needed. |

Interior Layout

Once we are satisfied with

the lines of the hull, and the mast and daggerboard locations

have been determined, we can develop an interior arrangement

that will provide for safety, passenger comfort, and structural

integrity. Because Nernah has been designed to be operated

under power, she must meet U.S. Coast Guard level flotation

requirements. Her wood hull provides a portion of the requirement,

but some additional buoyancy is needed. By fitting an enclosed

seat across the width of the stem, we can supply the needed

swamped buoyancy, give additional stiffness to the transom,

and provide dry seating (see Figure 1).

To provide buoyancy forward,

we can partition off a portion of the hull from just aft

of the stem heel forward. If we reinforce this chamber sufficiently,

we can step the mast to it, eliminating the need for a separate

mast partner.

The location of the rowing

thwart in small boats is always a dilemma. Do you position

it for best fore-and-aft trim when rowing solo, or with

a load? In Nemah's case I have opted to move the thwart

forward of the ideal solo

location for two reasons: (1) it is better to trim a bit

bow heavy when lightly loaded than to trim very stern heavy

with a load on, and (2) under power, the operator will need

to be located fairly far aft, so any passengers should be

seated a bit forward of the center of buoyancy to bring

the hull into trim.

Structural Considerations

Boats are subjected to a

variety of forces, both in use and during storage, We must

account not only for forces generated by the rig under all

points of sail; but for forces applied to the rail structure

under oars, for the thrust of the engine and its associated

twisting forces, for the stresses applied to the daggerboard

well in a grounding, for the localized loading applied to

the hull bottom when someone steps into the boat, and so

forth.

My approach has been to

consider these forces from two standpoints; resisting distortion

that could affect performance, and preventing structural

failure. While these two factors are certainly related,

they are not one in the same. Consider the case of the $39.95

rubber boat under oars the "hull" will flex to

such an extent that the efforts of the oarsman

are almost totally negated, while the structure itself is

in no danger of

failure. Another example of this problem is the loss of

sailing performance noted when the forestay slackens on

a sloop, distorting the shape of the jib. Structural distortion

can also have an emotional effect. Noticeable "give"

when you step into a boat or "flexing" of the

rails under oars can make you uneasy at times.

In open boats such as Nemah,

the two areas where distortion and/or structural failure

are likely to be a problem are both related to the rail

structure. The first is hull twist, particularly under sail,

and the second is rail flex under oars. Traditionally, frames

and bulkheads have been used to maintain hull shape, although

in practice they do little to resist twisting

forces unless used in conjunction with an adequate rail

structure. The rail structure must be stiff enough so that

twisting forces are resisted by the triangular assembly

whose sides are formed by the rails and transom. (This makes

more sense if you realize that hull twist translates to

gunwale movement fore and aft, and that the connection of

fairly stiff rails at the bow will do much to arrest this

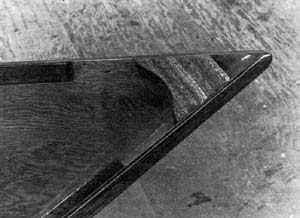

movement) In relatively light boats, this can be accomplished

by installing a trussed rail assembly (see Figure 2).

Figure

2

With trussed rail structures

that are made up only of blocks, such as those used in some

canoes, twisting forces caused by the use of oars can still

cause a noticeable flexing of the rails. To counter these

twisting forces, I have adopted the practice of fitting

short ribs between the inwale and the side panel. These

"riblets" usually terminate about four inches

above the chine. Besides adding stiffness in the area of

the oarlocks, these ribs are useful for distributing the

load of the thwart (see Figure 1).

The bending loads on these

rail structures are greatest in the middle and decrease

towards the ends. For this reason, it is acceptable to decrease

the separation between the rubrail and the inwale as it

approaches the ends of the hull, and to actually terminate

the inwale just short of the quarter knees and breasthook

(see Figure 3). This simplifies their fitting to a great

extent.

Figure

3

Since Nemah's mast is to

be supported by the forward rotation chamber panel structure,

some consideration has to be given to transferring the sail's

forces to the rest of the hull structure. The simplest way

to do this is to locate the aft edge of the chamber close

enough to the rail structure that the fiberglass tape bonding

the chamber to the hull is integrated into the structure

of the rail itself (see Figure 4).

This relieves the side panel

of the need to absorb a lot of stress in a small area.

Plywood

Because we have given careful

attention to the distribution of stresses throughout the

boat, we can safely use 1/4" marine plywood for the

sides of the hull. Three-ply fir would be satisfactory in

this instance, while 4 or 5-ply mahogany would be a bit

stiffer and somewhat less likely to suffer damage from collision.

By scarphing the bottom

panel with its face grain running athwartships, 5/8"

5-ply fir marine grade plywood will be satisfactory. I generally

sheath the bottom panel inside and out with fiberglass;

outside for abrasion resistance, and inside for resistance

to impact damage.

In Part

III of the series we'll discuss bonding materials and

techniques, and then go through the actual process of fabricating

a plywood composite "shell."

Visit Tracy's website:

https://www.tracyobrien.com/

|