Custom Search

|

|

| sails |

| plans |

| epoxy |

| rope/line |

| hardware |

| canoe/Kayak |

| sailmaking |

| materials |

| models |

| media |

| tools |

| gear |

|

|

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter Comment on articles CLICK HERE |

|

|

| Volare – The Story So Far |

by Andrew Walters - Pelion - Greece |

We came to Pelion 5 years ago and after looking for several months we found a house on the south coast, 400 yards from and above the sea with views across the Aegean to Skiathos, Skopelos and Evia.

As with all things in Greece, things didn't happen in a straightforward way. The German owner died two months after we made our initial offer, leaving the house to a charity based in Germany. The charity wanted to sell the house to us but before the sale could complete the ownership of the property had to be transferred to the charity and registered to them in both Greece and Germany. This took 18 months. Fortunately we were able to come to an interim rental agreement with the charity, the single payment later being deducted from the sale price. Great! We had a house but at that time didn't own it, my property renovation plans couldn't commence because we didn't own it, so what to do? … yes, build a boat! At that time my knowledge of boats and the sea was limited, 12 years earlier I'd completed the Royal Yacht Association shore based day skipper course and done a few weekends yacht sailing as part of the sea based training, other than that … zilch! So I started Googleing 'boat plans' and, as one does, came across this site and several others including the Svensons boat site which was interesting because it included lots of designs for boats, mainly from the 1940's and 50's. I wanted to build something small – being my first boat building project I was well aware of the possibility of it ending up as a pile of firewood and (well, at least from my wife's point of view), the smaller that pile the better. Eventually I decided to build a William Jackson design called the 'Ace'. It was small, very stylish, didn't need lots of power but could handle it. I'd also come across the Sandeace website … it turned out that in the late 1950's the Sande boat works on the Hood Canal near Belfair, Washington produced their own version of the Ace, in essence, the same design but lengthened by a couple of feet. The website is run by a group of owner enthusiasts who have an annual rendezvous on the Hood Canal.

Four years on I still have her and I've in that time have seen ways in which improvements could be made. The 'Instant Boat' method had great appeal, I liked the idea that, by cutting out the developed shapes of all the major parts, a boat could be assembled that needed minimal framing and once taped and glued together became a strong monocoque structure.

So (and in the words of Dave Gerr), I became 'nautically obsessed', looking at boats, reading about boats, about the theory, the resultant designs, the design software and all the time looking for yet not finding a design that I liked for my next boat. (I'd also gotten into restoring vintage outboard motors because a boat as stylish as the Ace needs one of those beautifully styled outboards of the mid 1950's – that was with great thanks To Max Wawrzyniak's articles here on Duckworks – but that's another story!) In tandem with this, in my architectural work I'd been increasing my use of 3D design software and realised that, having made a 3D model of a boat, it was possible to create the developed templates of the flat panels, make accurate drawings of all components and, provide construction sequence drawings and videos. So I decided to design my own boats. The Ace is a great little boat, but does have limitations here where the water can develop quite a chop ... sometimes unexpectedly. Last week the waves in the usual afternoon chop became noticeably larger than normal so we came home. The next day I learned that there had been an earthquake on Evia – lesson number 991 - sometimes the sea conditions are determined by things other than the weather! So, the next design brief developed, it needed to be capable in rough water so would have a higher sheer and more seaworthy bottom and maybe a console, be easy to build with minimal framing, avoiding rot causing water traps and incorporating flotation to make it unsinkable.

Out of this self imposed brief came 'Volare'

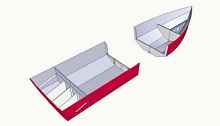

With a curved bow and straight stern, the stern section panels could all be straight cut. That, if the boat was made in two halves, joined by a midships frame, the assembly process would be easier because one would be assembling panels that were much smaller. This also enabled the two sub assemblies (bow end and stern end) to be built in a small workshop (or, for the single and pending divorcees - the living room) with final assembly being completed outdoors. Of course a strong connection between the frames is essential but this can easily be achieved by fixing the end frames of each assembly on the inside with glass fiber taped joints bedded in epoxy resin, bolting and gluing the mating frames together with epoxy resin, and applying another taped joint on the outside before covering the whole outer hull in glass fiber cloth/mat and epoxy resin. It's perhaps not surprising that the resultant design has a lot of similarities with the small outboard boats that are commercially available here yet Volare has one big advantage - weight. A 4.9m fiberglass boat here weighs over 800 lbs (and costs over 5,000 euros) - that's over twice the weight of the Volare Console version. This has a significant impact on the comparable power requirements, for example, according to the Crouch planing formula, the standard hull version of Volare will give the same performance as a production boat on 30% less power and the step hydroplane version (see below) will give the same performance on half the power.

The Step Hydroplane Version

Being 'nautically obsessed' led to my interest and curiosity in the wide variety of hull types. I kept reading favorable reports (by respected writers) of the step hydroplane and noting worthy examples such as the WW1 Thorneycroft MTB's - 40 feet long, almost 4 tons capable of 34 kts from 250hp and Bluebird K3, 23 feet long WITH A 2,150 hp Rolls Royce aero engine making the world water speed record of 130.91 mph in 1938. I'd also come across articles written in the 1950's that questioned the demise of this hull type.

The construction method of Volare enables a stepped hull to be built almost as easily as a flat hull and, because the front section is unchanged, the design for the step version can be produced as a supplement rather than a separate set of plans. In order to quantify the efficiency of a stepped hull I made a Crouch planing speed formula spreadsheet which enabled quick comparisons to be made of various hull type/power/displacement combinations. Whilst the results are formulaic rather than actual (and therefore cannot be guaranteed), they are encouraging, for example: Volare Console compared with Volare Console with step hull

Volare console with step hull (400 lbs) compared with a production GRP boat (800 lbs)

In making decisions relating to the 'what if's' of the various hull type/ power/displacement combinations, it quickly becomes apparent that there are many variables. For those interested a Crouch formula Spreadsheet (downloads file). Examples are listed. To assess your needs (or curiosity) just change the variables in the red boxes to see the results in the blue boxes.

What next? To the east of the Pelion Peninsula is the Pagasitic Gulf where the waters are much calmer. Mia and Zipper, my other two designs would suit these waters so the plan is to build one and keep it permanently moored there.

But there's also going to be a need for a boat capable of further exploration and excursions to the islands. Overnight accommodation will be needed to include toilet and washing facilities and fuel economy will be important – we know so many folks with large planing boats that never go far or never go fast because of the fuel cost. My initial ideas are for a fast, wave piercing displacement hull design. The question now is how to design in 'long and lean' yet design out 'wobbly' ... perhaps a catamaran. Watch this space...The build of Volare is scheduled for this autumn. Andrew shares his time between homes in the UK and Greece. Plans for Volare and Andrew's other designs can be seen in the Duckworks Store. |