Part 1 - Part 2 - Part 3 - Part 4 - Part 5

I finally got started on the new MiniPaw dinghy. I've had the stuff for for almost a year now. I've been working afternoons on it.

|

Starts with a stack of plywood. Both sides and both halves of the bottom get cut together, so they are exact duplicates. |

|

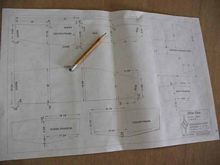

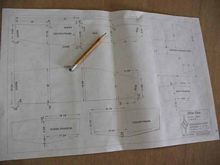

And of course, a set of plans. |

|

You do some measuring |

|

set some nails at certain points |

|

spring a batten on the curve |

|

cut out the panels |

|

and here's the finished sides and bottoms, rough cut. |

Yesterday we left with rough cut panels. Now we need to smooth the edges to the exact lines, which is best done with a hand plane.

|

Isn't this fun? My shoulder is yelling at me. |

|

Layout and cut out the bow and stern transoms. |

|

Again, spring battens for curves. |

|

Some more nails on points to transfer patterns. |

|

Transferring a pattern. |

|

And all the knees and gussets are done.... in just as few minutes. |

|

The boat gets a center frame of solid wood, with corner gussets and all those knees get glued together. |

|

Gusset's are epoxied and nailed with bronze boat nails. |

|

Boat nails are ring shanked - once in, they aren't coming out! |

|

Transoms get reinforcing pieces of solid wood across the tops. |

|

All epoxied |

|

And nailed |

|

Remember that center frame? Well, it all needed rounding and smoothing before going into the boat. |

|

And the tools of choice. A Shinto Rasp, a bastard file, and sand paper. |

|

We're gonna wire the boat together, so we need many short pieces of wire. The simplest way to get them is to wrap them around a 1" rod many times, slide the coil off, cut along one side, and end up with a bunch of rings. |

|

And those doublers on the bow and stern transoms need to be worked down to the correct size. More hand plane work. |

|

And now, finally, we begin to actually build the boat.

Here's the beginning of what we call "going 3D". |

|

Transoms are in. |

|

Side view with bottom installed. |

|

All 3D |

|

Here's the up front end. Ya gotta be careful now, or you'll look like you were in a cat fight from all the wires. |

Next Time: Filleting and taping; fitting interior parts

|