|

|

| Building

Annie - A Navigator 15ft Yawl - Pt 1 |

| By Robert Ditterich - Geelong,

Victoria - Australia

|

|

| To

Part One

To

Part Two

To Part Three

A Pictorial Essay of a Navigator

Build

|

The cockpit bulkheads are formed from the seat

base, with a 9mm plywood arm overlapping it to form the stringer

supports and the seat backs and side deck supports. Because

the bulkheads are drawn at 1:5 scale and in two overlapping

parts, I found it helpful to loft full sized sections to check

measurements and enable accurate assembly. |

|

Here the 20mm doubler has been glued (oversize

to allow for fairing the hull into the transom) onto the 6mm

transom. |

|

20mm doublers added oversized, to allow for

the flair of the stringers as they come away from the transom.

|

|

This bulkhead has double hatches to go either

side of the mast. The workshop floor has gone back to bomb-site

status after just a few bulkheads. |

|

B2 having blocks attached to increase the gluing

area behind the stringers- which are very curved at this point.

|

|

Because John has given bulkhead details as dimensioned

1:5 drawings, I found it helpful to loft the full sized outlines

onto paper. This was particularly useful in fitting the two

part cockpit bulkheads, enabling accuracy in fitting them

together. |

|

Trying out a good Polyurethane glue to reduce

the amount of exposure to epoxy. It foams a little when going

off, filling voids. You can see it around the edges. |

|

Allowed myself the luxury of cutting the inspection

hatch holes freehand this time, knowing that they'll be covered

by the molding.

Here the symmetry and widths are being tested with a full

width batten before the glue sets. |

|

The two outer laminations have been roughly

cut using the more finished centre strip as a template. The

little piece of ply laying there will become a template to

make the centreboard later. It is a half male template at

the top and a half female template at the bottom. |

|

Using the main stem piece as a template to shape

the 2 doublers. A pattern routing bit (with a bearing) is

used. |

|

Never underestimate the potential of a spokeshave.

My old friend in the background lies ready to help when machines

are too clumsy. |

|

Rather than using a template to rout the whole

shape, I used the template to cut regular profiles across

both sides of the board, and then used power and hand planes

to take the surface down to the bottom of the profiles; less

noise. The router is kept at a constant distance from the

board, in the shape of the foil section, by moving over the

'bars'. |

|

The shape was developed from a full sized section

template, and the height was projected at many perpendicular

points to the surface, and at a height sufficient to clear

the bit at maximum depth |

|

2 full sheets of 9mm ply are scarfed together

for joining. The garboard (bottom) panel will be drawn... |

|

John's design for hatch covers seems very good,

but I couldn't bear to waste the cut outs from the hatch holes.

Cut them neatly with a thin blade and it saves the work of

making new infills. I have backed the holes with some thin

ply. |

|

These will help make a large volume of reserve

buoyancy forward of the mast, while also allowing the stowage

of gear. |

|

This stringer becomes the support for the cockpit

seat front panel, but also has the role of placing and supporting

many of the bulkheads during assembly. |

|

The keelson is 100 x 20. The dimension is cleverly

incorporated into the CB design, so make it accurate. |

|

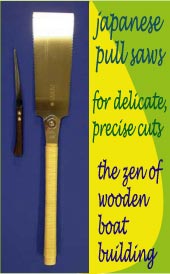

Because this had a chip on the edge from striking

a submerged screw in the previous boat build, I've used a

coarse carborundum water stone to cut back the secondary bevel,

removing the damage. This could have been done with a grinder,

but for such a lovely blade, I prefer to grind by hand, with

grit and water. |

|

Several nice jobs grouped together help concentrate

the mind onto the joys of sharpening. |

|

Coarse carborundum stone used to remove chip

on the secondary bevel. I will produce a straight, grey flat

area which will become shinier as finer stones are used. |

|

1200 Japanese water stone and honing guide removing

the scratches from the bevel caused by the coarse stone used

previously |

|

Despite the camera distortion, that centre board

(keelson) has parallel sides. This shot is in just because

I liked the shapes and colours. |

|

I include this because it illustrates

the designer's method for creating 'x-y' co-ordinates for

locating a fair curve on a grid. It works very well indeed,

but because the horizontal axis starts with a value of 157

instead of 0, a builder using the edge of the ply to mark

out the panel would waste almost enough to make the second

panel. Expensive stuff, marine ply! I recommend either reducing

all the relevant numbers by 157, or locate the ply on a backing

board in such a way as to allow the bottom curve to start

near the edge. |

|

At bottom left, the slot for the stem is nominated

and shown as 10mm, with 20 x 20 packers each side. The stem

diagram, by contrast shows the stem width to be 27mm at this

position. I chose to believe the stem diagram rather than

this one. Note also that on another diagram the king plank

width is shown wider for the yawl rig. |

|

If the rebates that you cut in the bottom of

the transom are snug and accurate, the transom will stand

up by itself and reassure you that your careful placement

of the stringers and keelson will have been worth the care

and effort. |

|

The old heavyweight is used to plunge cut along

the 2 lines. The ends are cut carefully with a jigsaw, because

there is framework under there and a blade hitting it end-on

can give you a scare. Plunge cutting is worth practising on

scrap if it intimidates you. A circular saw gives a much straighter

cut than a jig saw can. |

|

|

|

|